Description

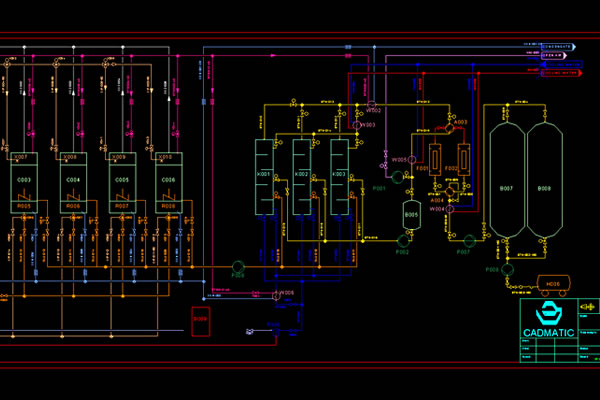

Plant Diagram, P&IDs

The CADMATIC Diagram module for flow diagrams, P&IDs and cabling diagrams is fully integrated with the 3D model. It provides the user with easy-to-use and efficient tools to create, modify and manage all kinds of diagrams.

- Flow diagrams, P&IDs, cabling diagrams

- Easy-to-use efficient tools to create and edit

- Concurrent multiuser/multisite environment

- Full integration with 3D model

- High degree integration with AutoCAD

Intelligent symbols, unlimited process size, control of revisions and advanced database management with user-definable report generator and script language are just some of the features of the Diagram module. Documentation for different piping and instrumentation diagrams, equipment lists, pipeline lists, and valve lists etc. can be automatically produced. Diagram can be used independently or with the 3D Design seat and can be interfaced with calculation software packages.

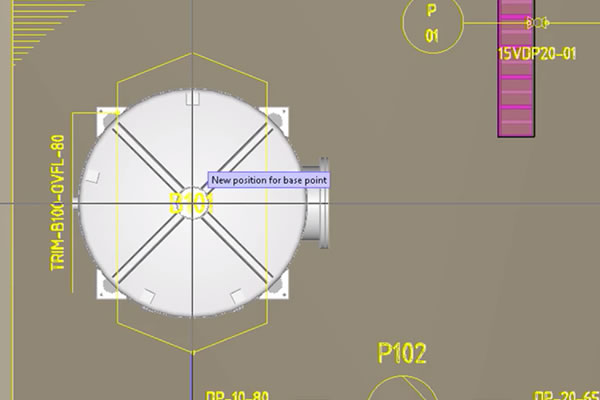

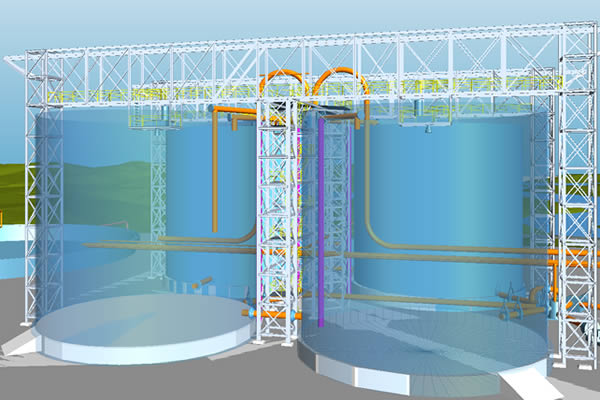

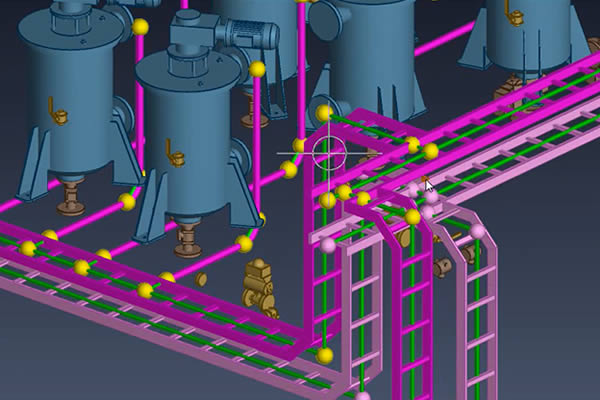

3D Model, Layout

CADMATIC 3D Plant Design is an integrated, database-driven design module. It provides powerful tools for 3D layout-, piping-, HVAC-, cable tray- and structural design of plants. It also produces information for construction, installation and ordering materials.

- 3D layout, piping, HVAC, cable tray, electrical and structural design

- Easy to create and modify 3D model

- Online and case-based clash detection

- Extensive libraries of standards and components

- Concurrent and unlimited multiuser environment

- Replication of projects for effective use of resources in globally distributed environments

CADMATIC Plant Design lets users concentrate on important tasks: creating equipment layouts, routing pipes and ducts, locating structural units, allocating service spaces and completing projects with laying electric cables.

At the same time the software takes care of the rest: controlling collisions and indicating connections according to diagrams, storing units for further use and checking the compatibility of components. At any point during the project documents can be extracted, various drawings and sketches generated and lists of materials, project follow-up data and eBrowser models for project reviews exported.

Structural Modeling

CADMATIC has a set of tools for creating the structural parts of a project, including plates, beams, foundations, stairs and ladders, railings, platforms and many others.

- Easy to create and modify steel constructions

- Specification-driven beam tools

- Unlimited foundation creation

- Templates for the most used structural units

Predefined structural units provide as easy way of creating constructions that are used repeatedly. Designers can set the types and standards of the units such as cages and ladders, for example, and then locate the main points of the unit in the model. All the required construction data can be extracted automatically, including MTOs, construction drawings and others.

Spoiler

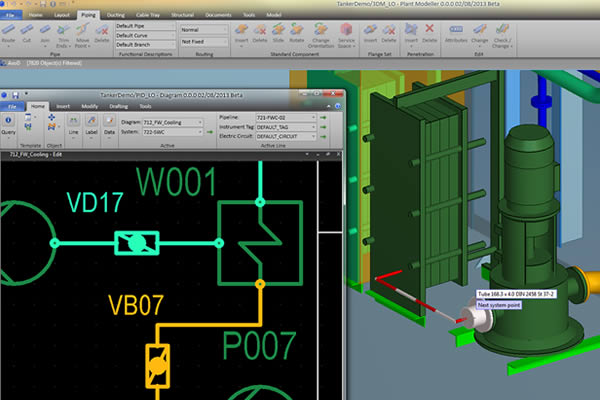

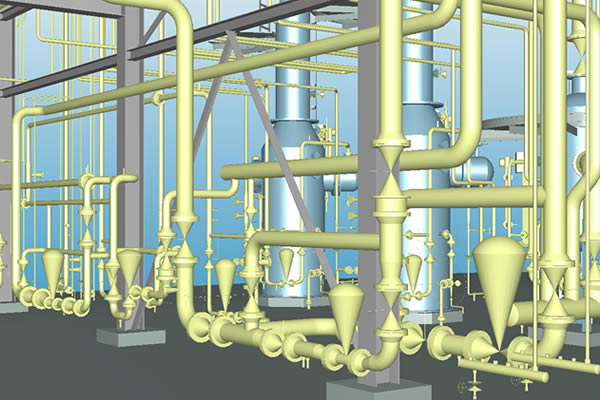

CADMATIC Plant design provides unique tools for piping designers to create complex piping designs. Piping design in CADMATIC is fully integrated with diagrams and the specification-driven pipe routing ensures that piping design is intuitive and easy.

- Specification-driven

- Integrated with P&IDs

- Easy to create and modify

- Online collision control while routing

- Simple navigation in 3D

- Extensive library of standard components

When doing piping design in CADMATIC the designer can rest assured that the correct components from the standards library are being used. By taking advantage of the suggested connection points according to the diagram and online collision control, error free piping design can be achieved. An extensive library of standards (DIN, ANSI, ASME, EN and others) are supplied with each software update. The piping design modification tools provide the possibility to change the pipe routing geometry, the nominal sizes of pipes and separate components. Pipe connection compatibility checks are performed automatically to prevent errors in construction.

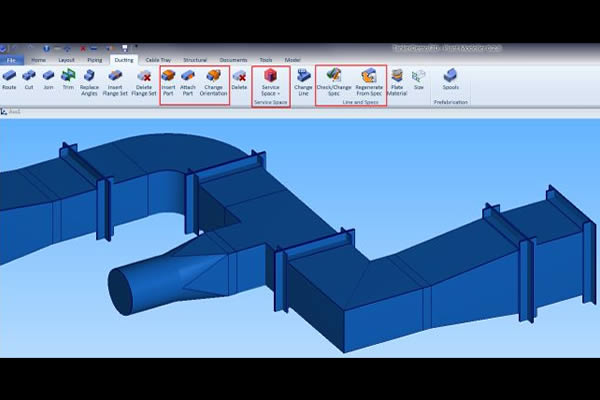

HVAC and Ducting

CADMATIC has an HVAC and ducting module for efficient 3D modelling and extraction of drawings and lists. The designer can simply concentrate on routing ducts while the system ensures that the correct components are used every time. This has been achieved with the aid of specification-driven routing, as well as automatically generated HVAC spools and Bills of Materials (BOMs).

- Route HVAC and ducts of any shape and easily modify designs on the go

- Specification-controlled use of materials and components

- Online and case-based crash control with all other project objects

- Automatic duct spools and BOM

The design of air ducts is based on specifications that consist of design rules. This ensures that the correct materials are selected according to the size-related duct part design rules, such as duct parts and curve radiuses, insulation materials and additional parts such as pins. It is possible to change the specification during duct routing, regenerate parts according to the ducting specification and see insulation in the 3D model to take advantage of space reservation and collision detection.

The Ducting Spool module automatically produces dimensioned prefabrication documents that can be generated in groups according to the logistical hierarchies inherited from CADMATIC containment management.

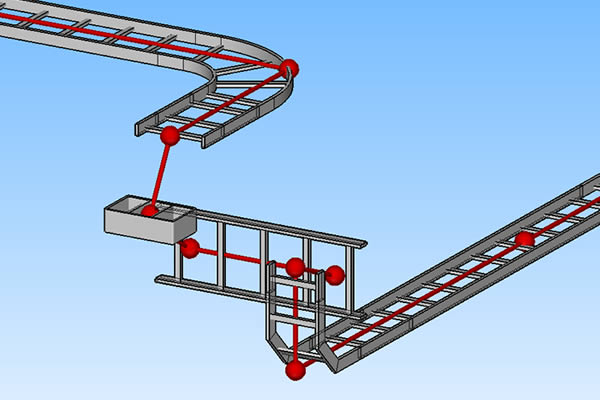

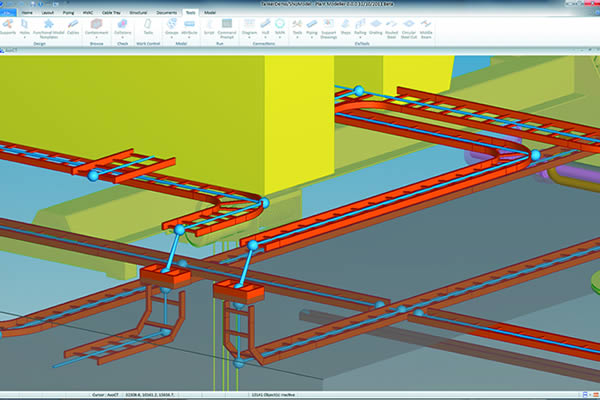

Electrical

CADMATIC Cable Router significantly saves man hours in cable routing and shortens the time needed for installation of pre-cut cables in plants. Cable Router comes with a fully automated routing functionality that selects the optimized routes for cables, calculates their cut lengths and checks cable way fill rates and possible collisions in cable jumps between cable ways.

- Automatic routing of cables with air jumps

- Customizable segregation rules and interference classes

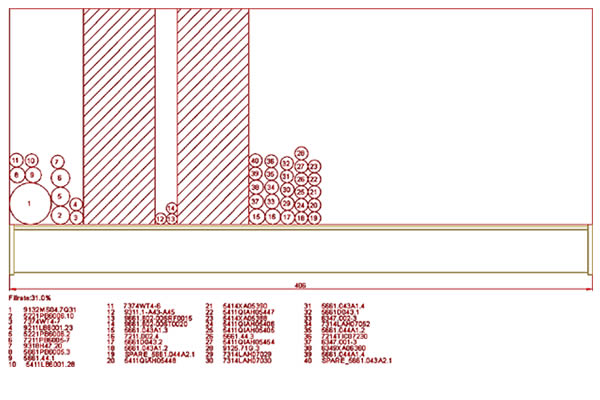

- Section view of location of cables on the trays

- Accurate pre-cut and penetration information for production

Cable ways can be routed with different types of components such as trays, ladders or cable conduits. The cable management tool creates a dynamic nodal network based on existing cable ways and penetrations in the model.

The system uses the nodal network to find the most optimal routes for cables between equipment and other objects and controls the status of cables. The user can easily manage which cables are routed, not routed, and for which cables the route has changed. Cable definitions can be imported easily from MS Excel for instance via the XML link from which the Cable Management tool automatically creates cables.

Cross section views can be generated for cable ways at the selected segment and penetrations (including sealed penetrations, for example Roxtec). It can be used for inspecting fill rates, cable assignment in segregations on the cable way or in penetrations. It is possible to attach the cross section views to construction drawings to provide additional information for installation on site. The system automatically produces cut length lists for cable pre-cut.

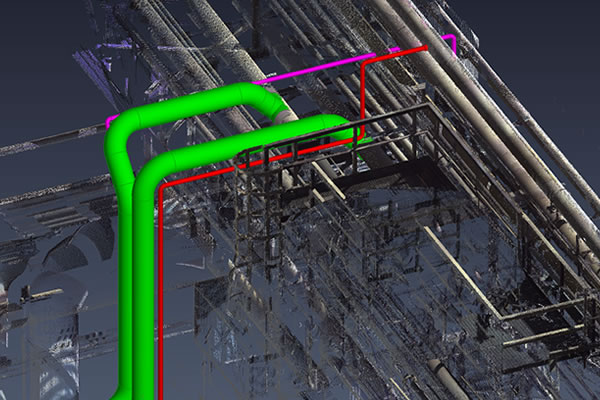

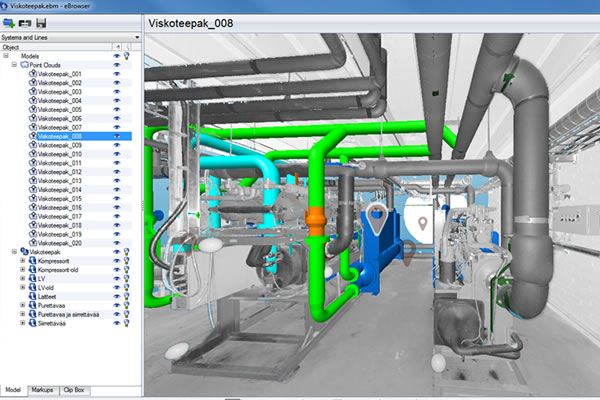

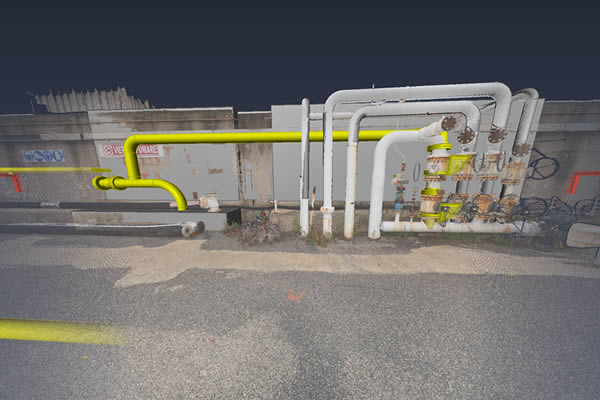

Laser Scan Modeller

CADMATIC Laser Scan Modeller is an integrated solution for seamless use of data from laser scanners to 3D models and construction data. It boosts the use of laser scanning technologies in design projects. You can utilize point clouds directly in the 3D design tool with the use of familiar design tools.

Benefit from viewing and examining an existing plant layout when sketching a new layout, use point clouds as references in measuring and fitting, while designing new items in detail or remodelling existing items. While remodelling you can directly use settings, the library and components of other CADMATIC modules for the correct attributes and materials.

- No restrictions on laser scanning equipment and formats of point clouds

- Intelligent map of scanners with annotations

- Create 3D components using specifications and library

- Model produced is fully integrated with other CADMATIC 3D Plant Design modules, including automatic ISO and BOM generation, project review in eBrowser and integration with eShare Information Management

- Reduce time for surveys, operational down time at the client’s facility, and the need for field trips in potentially hazardous environments

- Fewer unknowns and assumptions regarding existing constructions, reduction in re-work due to instant availability of accurate dimensions and spatial geometries

- Scope of changes can be estimated quickly

- Lack of as-built electronic documentation available from the owner/operator is no longer a need of concern

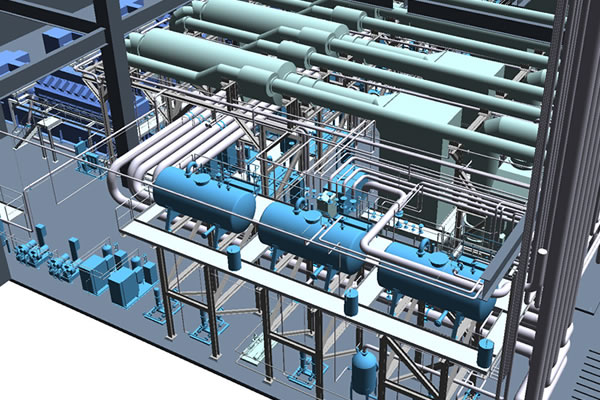

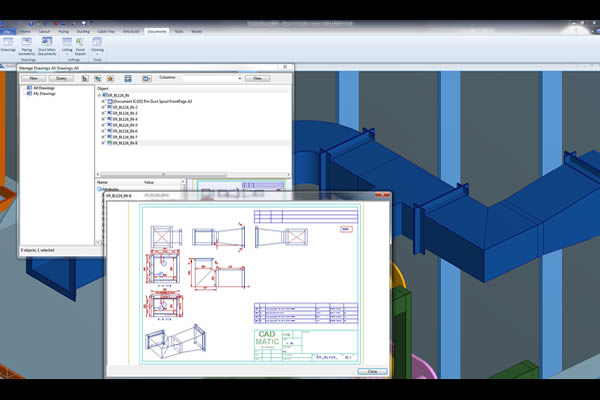

Construction Data

At any stage of 3D modelling the user can generate a wide range of documents for construction including layout drawings, sketches, piping layouts, isometric drawings for pipes, duct spools, unit and structural parts drawings, and extract BOMs and MTOs.

The inbuilt drafting tools allow fast and effective finishing of the drawings to be exported to DWG or PDF formats, or printed directly. Bills of materials and other construction data can be extracted in suitable formats: preliminary lists of materials, construction materials for zones, buildings and areas.

- No limitations in type and size of drawings

- Fully customizable output templates

- Multi user/multi site access

- Intelligent export to AutoCad or PDF

- Direct export to eShare for project handover materials

Interoperability, eXchangers

CADMATIC software has been designed to be as open as possible, to allow smooth cooperation, integration, and interfacing with other technology suppliers and software systems. CADMATIC’s open database and numerous interoperability functions enable data to be easily transferred between systems. Documents for construction can be output in the most common formats, such as DWG and PDF, and delivered in the required manner. Various eXchangers provide possibility to exchange data between different software programs with options to include meta-data or keep level of reference models only. The list below provides information on supported software systems and file formats, with additional details about the level of interoperability in each specific case.

Distributed Design (Plant)

CADMATIC offers an extremely robust yet resource-friendly project distribution system. It enables users to work simultaneously on the same project. This distribution system suits both large multinational operators and smaller companies and is called the CADMATIC Co-Designer.

Our Distribution design solution is based on a smart database-centric client server system that efficiently stores 3D Plant models, documents and component libraries in master and replica databases hosted by a database server system. Distributing plant design work globally or adding new design teams to a project can accomplished with ease.

Ensuring the integrity and security of project data at all times receives the utmost priority in the CADMATIC Distributed Design system. In globally distributed projects data is updated at set intervals between remote design sites via an online network such as the internet, or by simply exchanging the file in an email attachment. Designers can rest assured that the automatic replication system takes care of data synchronization, thereby ensuring that no design hours are wasted due to incorrect information.

Reviews

There are no reviews yet.